Induction Technology Corporation (ITC) designs and develops custom induction melting equipment. Contact us about your individual project requirements.

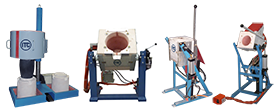

Custom Cube Melting Furnace

A custom ITC Power Cube induction melting furnace, with a nominal capacity of 95 kg Aluminum. This furnace features a “through the bottom” pouring system via crucible port with a plunger (sealing rod) and an isostatic pressure refractory lid which allows inert gas shielding and purge throughout the melt cycle. The inert system also aids to force material from the crucible during the pouring cycle. The furnace is beneficial because its design allows for >90% melt efficiencies and protects the customer’s process from external contaminates that can affect their specialized metal production. It also features:

Custom Shell Melting Furnace

A custom-designed steel shell melting furnace with a nominal capacity of 2.5 metric tons Aluminum. It features an axial aligned pouring system and isostatic pressure lid, which allows atmospheric inert shielding throughout the entire melt and pouring cycle. This design is beneficial because it allows the customer to produce high purity, oxygen-sensitive Aluminum alloys with strengths comparable to steel at 1/3 the weight. It also features:

REQUEST A QUOTE

Do you need help with choosing from our products?

Fill out this form to get in touch with us.

OFFICE LINE

OFFICE LINE