What is induction melting?

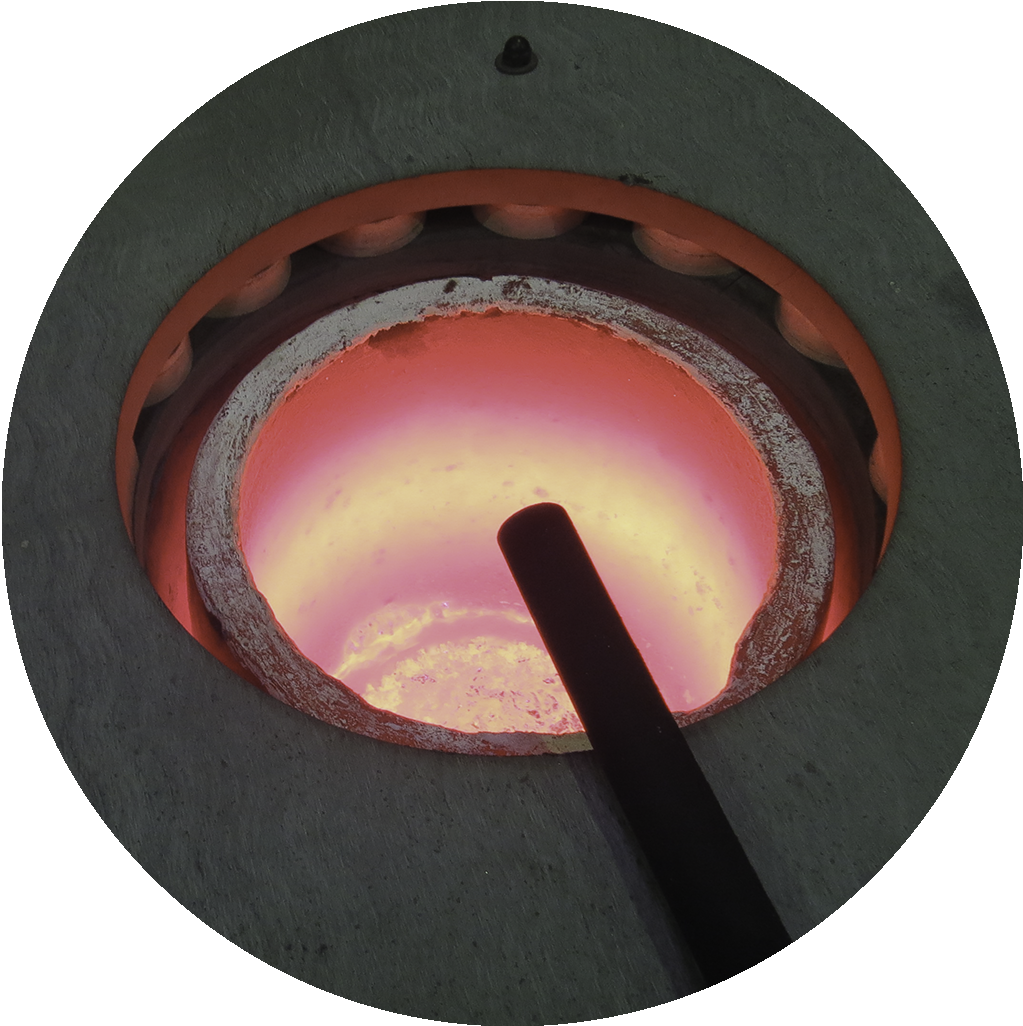

Induction melting is a cost-effective and energy-efficient way to raise the temperature of a metal or ore to its melting point and to hold that temperature to perform metallurgical processes such as smelting, alloying, mixing, and casting.

Benefits of Induction Melting:

- Energy efficiency

- Cleaner technology

- Increased productivity

Two types of furnaces are used in induction melting:

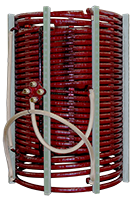

- Crucible induction furnace – it consists of a coil that encircles the crucible

- Channel induction furnace – it consists of one or several basins on which one or several channels passing through a coil are connected

Below are some examples of where induction melting:

Why Choose Us?

REQUEST A QUOTE

Do you need help with choosing from our products?

Fill out this form to get in touch with us.