ABOUT US

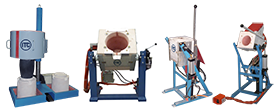

Induction Technology Corporation (ITC) is an international company which specializes in the design and manufacturing of complete induction melting and heating systems.

ITC was founded in 1979 with the main objective of providing superior service and innovative products for the induction melting and heating industry.

44 YEARS EXPERIENCE.

PROUDLY MADE IN THE USA.

Induction Technology Corporation History

Induction Technology Corporation was founded in 1979. The company was started with the main objective of providing superior service and innovative products for the induction melting and heating industry. ITC originally operated out of the founder’s garage in Huntington Beach, California. Throughout the years ITC moved into bigger facilities as it grew, finally landing in Apple Valley, California. The facility occupies over 30,000 square feet and was built on 5 acres of industrial property. ITC newest news is that as of June 2019 it has become a part of the UltraFlex Power Group. ITC has experienced steady growth during its 44 years being in business. The steady growth is attributed to its commitment to providing superior customer service and having the main objective of improving products and services continuously.

About UltraFlex Power Technologies

Founded and headquartered in New York, UltraFlex Power Technologies has provided industrial induction heating equipment and customer-focused solutions worldwide for over 20 years. UltraFlex has sales and support offices in the USA (New York and California), Europe (Bulgaria), India, and China, with additional support from our global distributors and partners.

How your business can benefit from our services

Implementing an UltraFlex induction solution will help reduce manufacturing costs, increase energy efficiency, improve safety and meet lean manufacturing objectives. Our technical support and maintenance services include preventative maintenance, equipment start-up and training, on-site or in-house repairs, and extended warranties. Above all, our team will help find solutions for the most complex heating applications and manufacturing system requirements.

About our systems

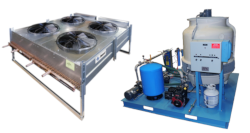

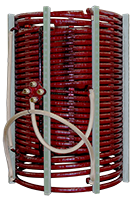

UltraFlex offers the most innovative, digitally controlled induction technology in the industry. Our patented SmartPowerTM modular systems feature the widest load matching capabilities in the market. This unique technology significantly reduces production downtime and operating cost. It allows more power to be added to the existing system when required. Our equipment incorporates many advanced diagnostic features and modular design advantages which optimize serviceability and maintainability. Our systems can be easily integrated into manual processes or fully automated production lines. Our engineers can help you develop custom induction heating and melting equipment, OEM modules, or complete turnkey systems.

Certifications

Our equipment is supported by a global network of ISO 9001 certified factories, sales and support offices, and application labs. Our equipment is CE marked and meets the current WEEE, RoHS, and Reach directives. Additional certifications, such as UL and CSA, are available upon request.

Research & Development

UltraFlex has three R&D labs to assist with the most complex induction heating and melting applications. We offer thermal and electromagnetic modeling services. UltraFlex has developed many innovative solutions for our customers’ most demanding applications.

Downloads

WHAT’S NEW FROM ITC

Read about the latest happenings at ITC!

ITC participates in Metal Casting Congress 2024

ITC participates in Metal Casting Congress 2024: Showcasing Induction Heating Solutions ITC is happy to announce its next participation in the Metal Casting Congress 2024, organized [...]

Melting System – In Stock and Ready to Ship

ITC Designed & Manufactured Melting System This comprehensive melting system includes a power supply, a furnace that can be hydraulically tilted, a modular wrap-around deck with [...]

Join ITC at the 70th ICI Technical Conference and Expo 2023

We are delighted to announce that Induction Technology Corporation (ITC) will be showcasing at the prestigious 70th ICI Technical Conference and Expo 2023. Join us at the esteemed Da [...]

REQUEST A QUOTE

Do you need help with choosing from our products?

Fill out this form to get in touch with us.

OFFICE LINE

OFFICE LINE