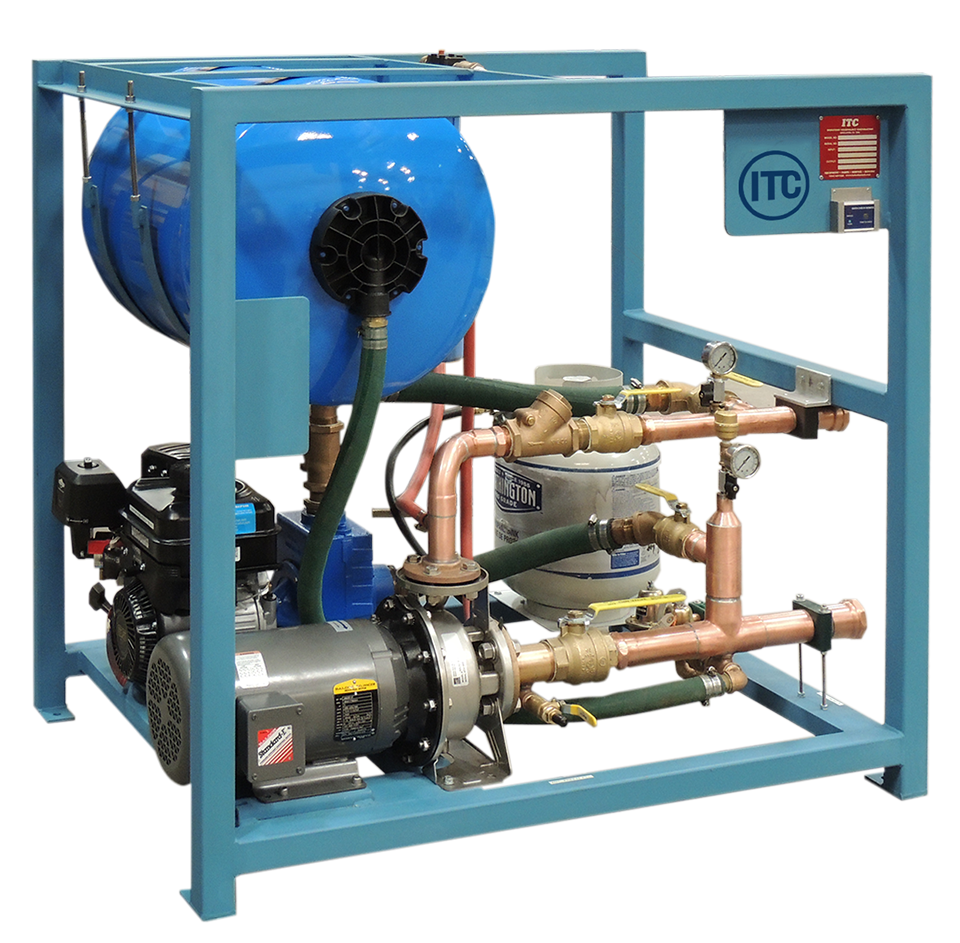

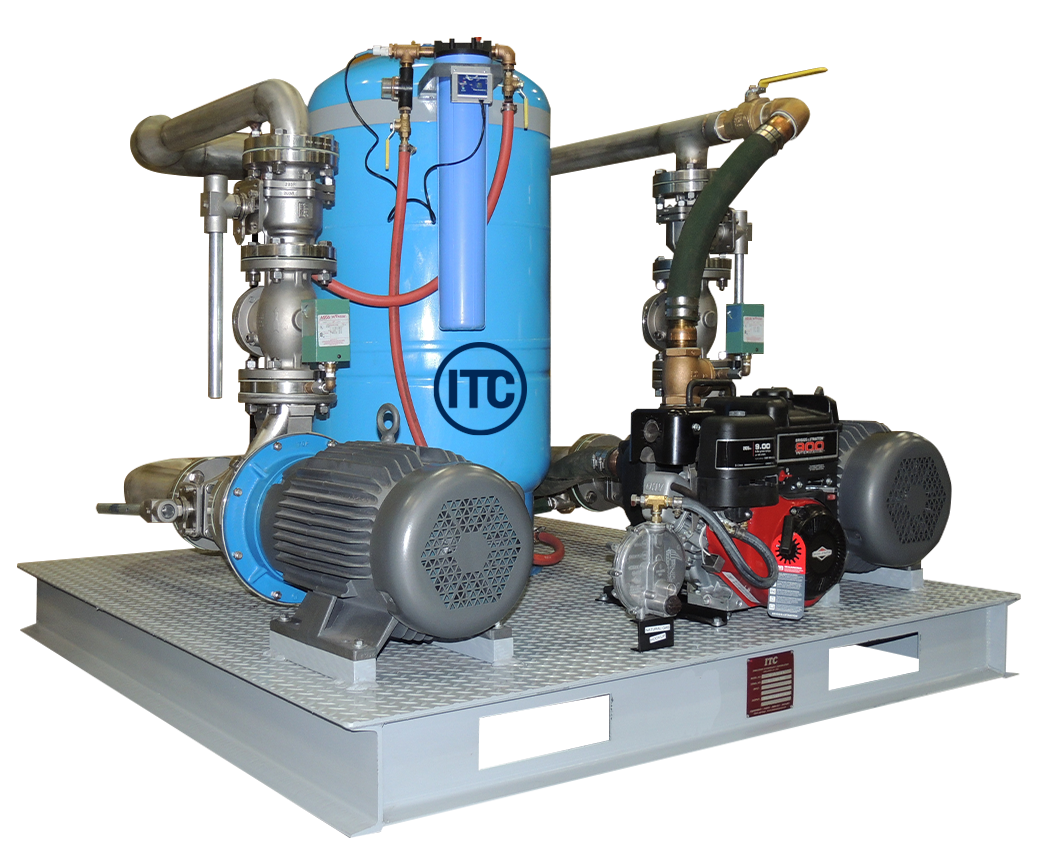

Single & Dual Water Pump Module

Both types are designed for closed-loop type water cooling and recirculating systems. The Single Pumping Module includes 1 water pump. The Dual Pumping Module includes 1 main water pump and 1 stand-by water pump. These water pumping modules are designed for maintaining proper water flow as the water is recirculated throughout your induction system.

Single Water Pumping Module

Features

Optional Features

Dual Water Pumping Module

The Dual Pump Water Module has the same features as the Single Pump Water Module, the following are additions:

Features

Optional Features

Downloads

REQUEST A QUOTE

Do you need help with choosing from our products?

Fill out this form to get in touch with us.

OFFICE LINE

OFFICE LINE