Induction melting furnaces are used in a variety of industries, including foundries, steel mills, and metalworking plants. These furnaces use electromagnetic induction to heat metal to high temperatures, which can cause significant wear and tear on the furnace components. Cooling systems are used to maintain the temperature of the furnace components and prevent damage due to overheating. In this article, we will discuss the different types of cooling systems used in induction melting furnaces.

Open Cooling Systems

Open cooling systems use water to cool the furnace components. Water is circulated through the components, absorbing heat and carrying it away. This type of cooling system is simple and inexpensive, but it can be less efficient than closed systems. Open cooling systems are prone to evaporation and contamination, which can cause the water to become less effective at absorbing heat. Additionally, open systems can lead to water waste, as water must be replenished regularly due to evaporation.

Closed Cooling Systems

Closed cooling systems use a heat transfer fluid, such as oil or glycol, to cool the furnace components. The fluid circulates through the components, absorbing heat and carrying it away to a heat exchanger. The heat exchanger then transfers the heat to another medium, typically air or water, which dissipates the heat into the environment. Closed systems are more efficient than open systems, as they are less prone to evaporation and contamination. Closed systems also require less maintenance, as the fluid does not need to be replenished as frequently as water in open systems.

Open/Closed Cooling Systems

Open/closed cooling systems combine the benefits of both open and closed systems. They use a closed loop system to circulate a heat transfer fluid, which is then used to cool the furnace components. However, instead of dissipating the heat into the environment, the heat transfer fluid is circulated through an open cooling tower, which uses air or water to dissipate the heat. This type of system is more efficient than open systems, as it reduces water waste and is less prone to contamination. Open/closed systems are also less expensive than fully closed systems, as they do not require a heat exchanger.

Cooling systems are an essential component of induction melting furnaces. They help to maintain the temperature of the furnace components and prevent damage due to overheating. Open, closed, and open/closed cooling systems are the three main types of cooling systems used in induction melting furnaces. Open systems are simple and inexpensive but less efficient than closed systems. Closed systems are more efficient and require less maintenance, but they can be more expensive. Open/closed systems combine the benefits of both open and closed systems, making them an excellent choice for many applications.

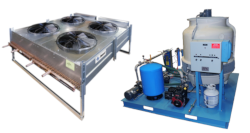

The choice of cooling system depends on the specific requirements of the furnace, the needs of the application and the geographic location. Based on this, ITC will provide the optimal cooling solution, utilizing one of our cooling tower types – Open Evaporative, Open/Closed Evaporative, Closed Dry or Adiabatic or refrigerated chillers. More information on the cooling systems we offer can be found here