Open Evaporative Cooling Systems by ITC

ITC produces induction melting furnaces, commonly used in various industries to heat and melt metals. These furnaces require a cooling system to prevent the furnace components from overheating and sustaining damage due to high temperatures. One of the most cost-effective and efficient cooling systems for induction melting furnaces is the open evaporative cooling system. In this article, we will discuss how these systems work and their advantages for induction melting furnaces.

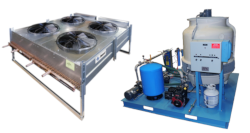

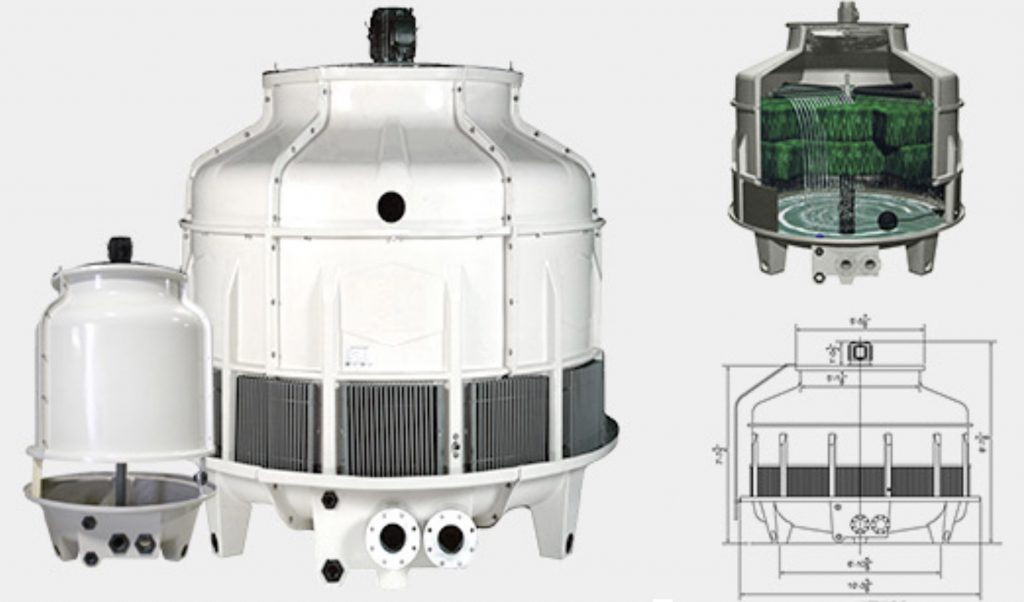

Open evaporative cooling systems use water as the cooling medium to remove heat from the furnace components. The water is circulated through pipes or tubes that are in contact with the furnace components, absorbing the heat and carrying it away. The water is then sent to a cooling tower, where it is cooled through the process of evaporation. The cooled water is then recirculated back to the furnace components to continue the cooling process.

Advantages

- Cost-effective: significantly cheaper to install and operate compared to other cooling systems, such as closed-loop systems, which require a heat exchanger.

- Energy-efficient: require minimal energy to operate, as they rely on the natural process of evaporation to cool the water. This makes them an energy-efficient cooling solution.

- Low maintenance: require minimal maintenance, as they do not use pumps or heat exchangers, which require regular cleaning and maintenance.

- Eco-friendly: use water as the cooling medium, which is an abundant and renewable resource. The water is continuously recirculated, reducing water waste, and there are no harmful chemicals or refrigerants used in the process.

- High cooling capacity: have a high cooling capacity, making them suitable for high-temperature applications like induction melting furnaces.

Limitations

- Water quality: susceptible to contamination due to the use of water as the cooling medium. Water quality needs to be maintained to prevent scaling, fouling, and corrosion of the furnace components.

- Environmental factors: influenced by environmental factors such as humidity and temperature. High humidity and low temperature can reduce the cooling capacity of the system, affecting its efficiency.

Open evaporative cooling systems are a cost-effective and energy-efficient cooling solution for induction melting furnaces. They are easy to install, require minimal maintenance, and have a high cooling capacity. However, water quality and environmental factors need to be considered when using open evaporative cooling systems. Overall, open evaporative cooling systems are an excellent choice for customers looking for an eco-friendly and cost-effective cooling solution for their induction melting furnaces.

Find out more about the different cooling system types ITC offers.