Rebuilding an induction furnace requires specialized knowledge and expertise in the field of induction heating. The specific steps for rebuilding an induction furnace may vary depending on the type and size of the furnace, as well as the extent of the damage or wear. However, here are some general steps that are typically involved in rebuilding an induction furnace:

- Assess the condition of the furnace: Before you can begin rebuilding an induction furnace, you need to determine the extent of the damage or wear. This may involve conducting a visual inspection of the furnace, as well as testing the power supply, coils, and other components.

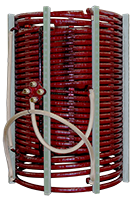

- Identify the necessary repairs or upgrades: Based on your assessment of the furnace, you should identify the repairs or upgrades that are needed. This may include replacing damaged coils, upgrading the power supply, or retrofitting the furnace with new controls or sensors.

- Order any necessary parts or components or fabricate them.

- Dismantle and clean the furnace:

- Make repairs or upgrades: This may involve rewinding coils, replacing damaged components, or upgrading the power supply or controls.

- Reassemble and test the furnace: Once all repairs and upgrades are complete, you can reassemble the furnace and test it to ensure that it is functioning properly.

Rebuilding an induction furnace can be a complex and challenging process, and it’s important to work with experienced professionals who have the knowledge and expertise to ensure that the furnace is rebuilt to the highest standards of quality and safety.