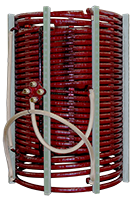

Induction Technology Corporation has specialized in rebuilding and manufacturing custom inductors. Our induction melting coils have the mechanical strength to withstand the severe conditions of a foundry environment. High diametrical and high-temperature insulating materials are used for all coils.

We received a 17lb induction coil for rebuilding. The repair process includes evaluating grout removed, replacing the broken top plate with the new one, and painting the inductor.

The recycled induction coil was shipped to the customer. You can see the before and after pictures of it below. ITC works on a wide range of coils for induction melting applications.

Reach out to us today regarding your standard or custom induction heating and melting applications. Learn more about our induction melting equipment.